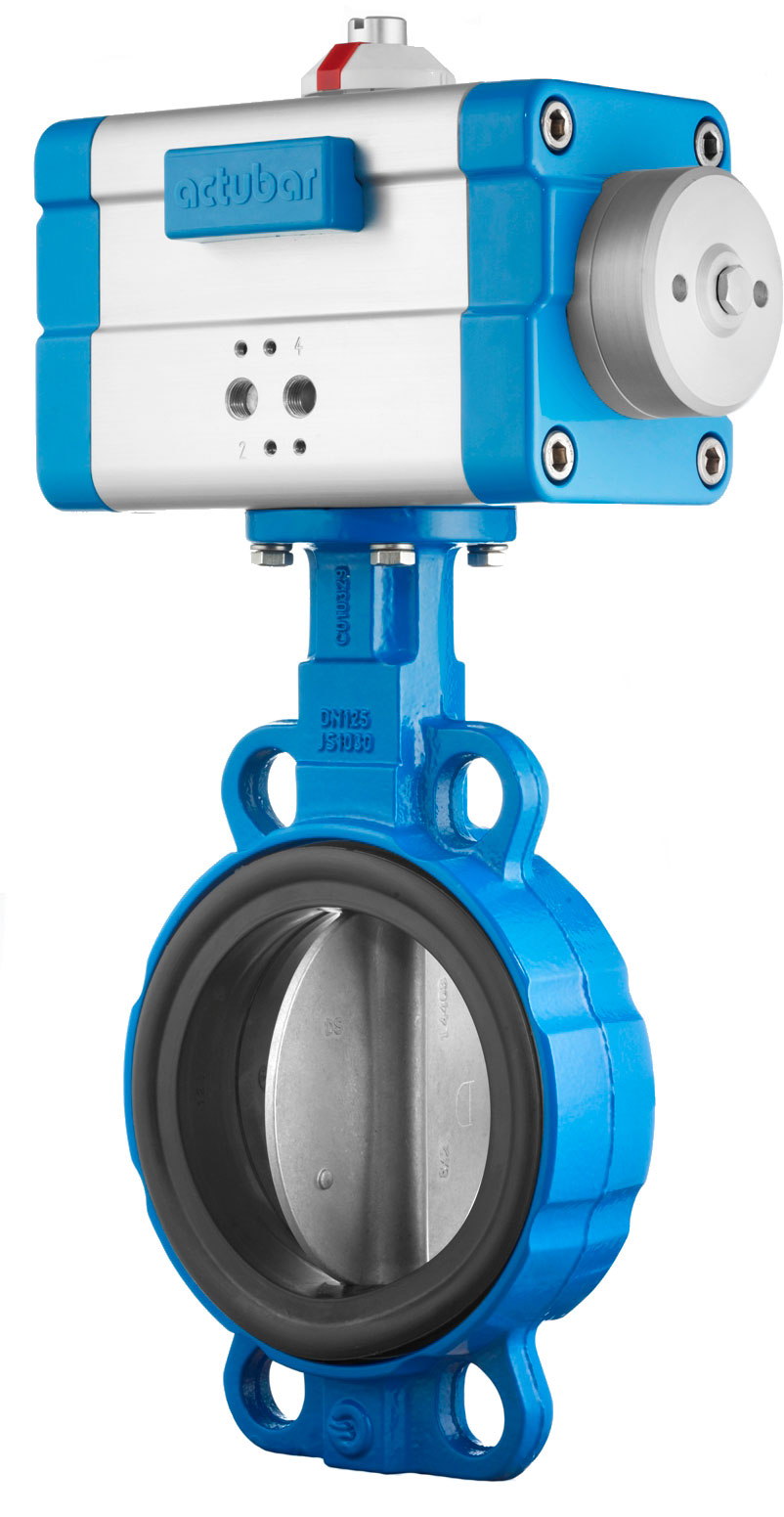

Pneumatic actuator type actubar®

with hydraulic damper

Product description

actubar is the latest generation in our range of

pneumatic actuators. Externally unmistakable and

technically

unique, the actubar offers new advantages

and uses. Technically speaking, actubar is the

main component in the novel valve control system

bar-vacotrol.

Working together with our directly-mountable system

components as bar-positurn or any other positioner

of the system for actubar is monitoring and regulating

automatic valves economically and effectively.

Objective

The hydraulic damper is an additional module for

lengthening the actuation time. An evenly constant

actuation speed is achieved through a piston which

oscillates inside a cylinder containing hydraulic

medium.

Torque remains the same and sudden movements

are avoided so that pipework, valves and actuator

are intrinsically protected.

Hydraulic dampers are deployed where there are

slamming valves such as double-eccentric butterfly

valves and used for preventing water surges.

And furthermore, it is possible to dictate whether

the damping effect is only present at the end

positions or ensures an even speed over the whole

pivoting angle.

Layout of the hydraulic damper is compact. The

module has been designed and constructed to be

secure against manipulation, so that unplanned

changes in the settings are not possible.

Deployment

This unique construction of the actubar allows addition of components in accordance with VDI/VDE 3847 and best of all, without hoses or pipework.

- Control and end switch boxes with solenoid valves can be added directly without additional piping and together form a compact unit with the actubar.

- All commercially available signalling units can be enhanced using the standardised interface VDI/ VDE 3845.

- End positions are adjustable between +5° and -10°in the 0° – and 90° position.

- Flexible automation of valves via various ISO-F flange faces per actuator size.

- Optional coatings and materials enable deployment even in aggressive environments.

- Long service life is achieved through slide bearings on all moving parts.

- An internal octagon in the pinion enables actubar to be universally mounted onto valves with parallel or diagonal switching angle position.

- The blowout-safe pinion minimizes danger of accidents.

- Extremely long switching times can be achieved.

- A smooth, even movement of the valve is assured independent of the operating conditions.

- A soft arrival at the end position is achieved.