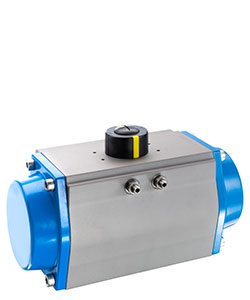

bar-agturn - the versatile actuator

Objective

With 40 years of experience in automation we are able to meet the current requirements of the valve market and together with the bar-agturn we have developed a new pneumatic quarter-turn actuator for our diverse customer groups.

Thanks to its special design, robust construction and great versatility in technical characteristics, we fulfil the demands from the plant designer and plant manufacturer to the user.

This covers a very wide range of torque values and swivel angles.

Use

- A suitable rotary actuator is available for each application of shut-off valves due to 18 different sizes and torques from 2 to 13.040 Nm.

- The high-quality powder coating of the cap and housing made of hard-coated aluminium allows the usage even in aggressive environmental conditions.

- The solenoid valve interface is located high on the profile and easily accessible which optimizes the installation of pilot valves.

- The end position adjustment on the opposite side of the solenoid valve connection facilitates the adjustment process.

- The standardised interface VDI/VDE 3845 can be used to set up all commercially available signal and control devices.

- The position indicator is part of the product which is equipped with variable clips for displaying the valve position.

- The end positions can be configured between 0° and 90° as well as from + 5° to -5°, whereby the valve can be optimally adjusted.

- There are 2 ISO flange patterns available for most of the sizes per each actuator size to ensure flexible automation of valves.

- The octagonal pinion connection adapts a parallel or diagonal selector shaft alignment of the valve and ensures a space-saving actuator construction.

- Simple assembly and disassembly of the safety springs which are designed for a balanced ratio between pneumatic torque and spring torque.

- Each control pressure is assigned to a defined number of springs and facilitates the actuator selection based on the torques.

- A laser engraving on the actuator housing marks the flange patterns and air connections for a clear allocation.

- The serial number is also laser engraved; this helps to trace the actuator manufacturing at any time.

- Precisely milled piston tooth system ensures smoother running, optimum torque and low wear.

- A long service life is achieved by using the plain bearing for all moving parts.

- The actuators cover a wide range of applications thanks to the actuator variants with different swivel angles.

- A reduced stock level is achieved by using identical caps for single- and double-acting actuators.